Capturing the smallest, hidden details with Photonic Science X-ray cameras.

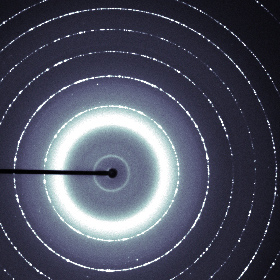

X-Ray Powder Diffraction

X-ray powder diffraction method is one of the few non-destructive methods that permit the identification and the elemental analysis of materials.

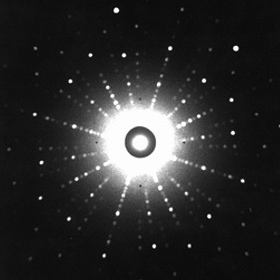

Laue & Crystal Orientation

The Laue method helps in determining the orientation of single crystals using white radiation in a reflected or transmitted geometry.

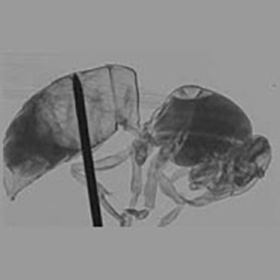

X-ray Micro Tomography

X-ray Tomography allows a 3D reconstruction from a series of 2D radiographs, each for a different angular position of the sample, and this can be done even down to sub-micron resolution.

Contact Us

22 Theaklen Drive,

Saint Leonards-on-sea,

TN38 9AZ,

United Kingdom

Phone:

+44 (0)1424 444883