News

Interview with Christian Roethel Piezocryst-Laue Crystal Orientation

5th Nov, 2020

In this interview, Christian describes how the Photonic Science Laue Crystal Orientation System has helped in the manufacturing process for their high precision piezoelectric sensors based on gallium phosphate crystals.

Download the pdf Laue system for Gallium Phosphate High Precision Piezoelectric Sensors

Christian Roethel, has a PhD in X-ray Diffraction from the Technical University of Graz. He joined PIEZOCRYST ADVANCED SENSORICS GMBH in 2018 as the head of sales and the product management team. Christian is involved in the products from conception through to sales and marketing and is the applications expert.

Piezocryst, are part of the AVL group, who are focused on the development of combustion engines and more recently electric engines for the automotive industry.

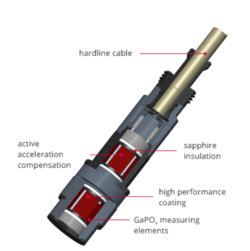

High Temperature Pressure Sensor

A big part of the engine is the measurement of the pressure that is generated during the combustion in the cylinder. Historically this was AVL’s main application. In 2004 Piezocryst was founded as a new spin-off company. They saw potential to take this expertise, accumulated over decades and apply it to applications outside of the automotive industry with a focus on combustion monitoring in energy gas turbines.

Piezocryst, manufacture extremely high precision piezoelectric sensors for the above industries. Finding the correct mixture of materials to manufacture these sensors is a challenge due to the harsh conditions in these applications.

At the heart of the sensor is a single crystalline material called gallium phosphate. This material is very stable when in extremely high temperatures. Piezocryst has their own crystal growth processing facility and is the only company worldwide that grow single-crystal gallium phosphate for these high precision sensors.

Piezocryst CP-Series pressure sensors for gas turbines and high temperature applications

The gallium phosphate is then combined into metal housings made of nickel-based alloys as they need to operate at very high temperatures up to 700˚C, for example in gas turbine combustion chambers. We need special alloys because they need to remain strong and hard, to withstand internal stresses and strain due to thermal expansions.

Each application requires different materials as they have different constraints for example:

• Combustion Engines for motorsports need to withstand peak pressure of several hundreds bar

• Gas turbines requirement have a lower pressure constraint of around 50 bar but require the resolution of pressure oscillation of a few millibar.

We are experts in developing the suitable material for our sensors to fit for each application and its temperature and pressure constraints.

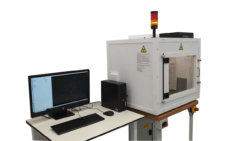

In 2020 Piezocryst took delivery of a Photonic Science Laue Crystal Orientation System for their Crystal Growth Facility.

Photonic Science Laue System

The main issue of the piezoelectric effect is that it is an anisotropic effect. This means that the orientation in space is very important to get the measurement that you are trying to achieve. We use the Photonic Science Laue system to establish the main crystal axis. Based on the defined crystal axis we can cut the crystal along the correct direction to achieve the desired accuracy we need for our measurements.

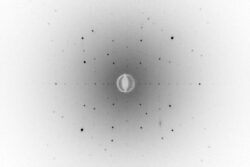

Laue image gallium phosphate

There are different kinds of Piezoelectric effects*. There exist longitudinal effects and transversal effects and we need to cut the crystal along the correct direction to make the crystals suitable for the requirements our customer expect. The Photonic Science Laue system gives us precise knowledge of this crystal axis and this helps us to improve the quality of the manufacturing process and product.

*(This refers to a change in electric polarization that is produced in the crystal when they are subjected to mechanical stresses. This stress-dependent change in polarization manifests as a measurable potential difference across the material).

Laue image of our gallium phosphate (GaPO4) crystal along the x-direction. We used 853 x 570 resolution for a quick alignment check (as used in this image) and for the final alignment at 2,559 x 1,710 resolution is used to achieve the optimum precision crystal cuts which down to less than 0.1° accuracy. Exposure is between 20 and 300 seconds respectively.

Photonic Science & Engineering would like to thank Christian Roethel and Piezocryst for their contribution to this article and the images provided.

Piezocryst the only company worldwide that can produce a single crystal gallium phosphate (GaPO4) and then process it into a high-precision product.

Piezocryst manufactures crystal elements in a very complex process. First, the single crystal GaPO4is examined down to the smallest flaw in the interior of the crystal in an optical scanning process. Then, pure GaPO4 is processed mechanically under tight angular tolerances, so that actual sensing elements develop. Each of these sensing elements is visually inspected for perfect corner and edge qualities and only top quality elements with the lowest height tolerances are utilized in the sensors. This process is responsible for the high signal quality and the low serial dispersion of Piezocryst sensors, but also contributes significantly to a longer product life.

If you have enjoyed this interview with Christian Roethel and would like more information about our Laue cameras, simply contact a member of the Photonics Science team today.

Download the pdf Laue system for Gallium Phosphate High Precision Piezoelectric Sensors