News

High-Throughput Laue Diffraction Systems

4th Nov, 2020

Laue diffraction occurs when a polychromatic X-ray beam impinges on a crystal. This unique reflection geometry was first discovered by German physicist Max von Laue who shone an X-ray beam through a copper sulfate crystal in order to record its diffraction properties. This unique diffraction pattern is intrinsic of crystal orientation, which provided the basis for new methods of optical crystallography. At Photonic Science, we provide a suite of high-throughput Laue diffraction systems that can assist with single-crystal orientation analysis and new innovative crystal growth such as geometrically-confined lateral crystal growth.

Laue Diffraction Systems: What You Need to Know

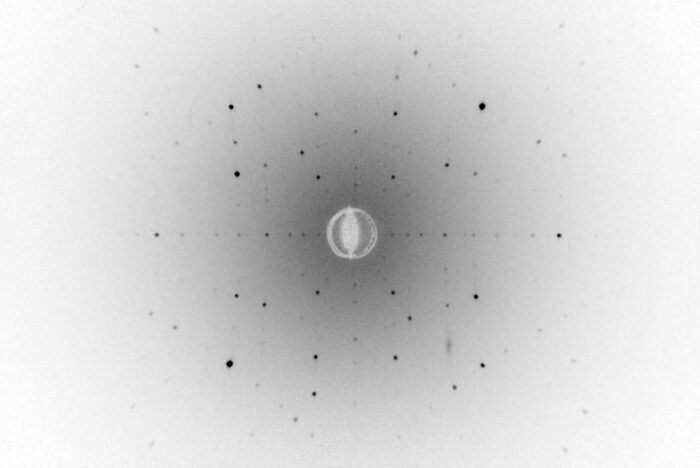

The Laue technique uses a well collimated low energy X-ray beam to record the characteristic diffraction pattern of a stationary single crystal. You shine this beam through a detector onto your sample and – provided reflected signals satisfy Bragg’s law – the detector records the characteristic set of diffraction spots. Other detection geometries, like Laue transmission, are only suitable for thin crystals.

Your Laue diffraction system also needs to use polychromatic X-rays with a continuous spectrum of Bremsstrahlung, or “white”, radiation. This is to ensure that each spot can be indexed to a specific reciprocal lattice point (RLP) in the crystal. The relationship between spot intensity and RLPs is complex in Laue diffraction – but the pattern can provide extremely valuable insights into crystallographic orientation.

Our Approach to Laue Diffraction Systems

At Photonics Science, we have developed a range of turnkey Laue diffraction systems using intense “white” beams with backscatter Laue detection. We use a high brilliant X-ray detector to generate an intense beam on an order of 9 – 29 keV focussed into a spot of no greater than 200 micrometres (μm). This translates to less than 0.3 mm on-sample, making it ideal for extremely small crystals or small grain polycrystalline structures.

As the sample is irradiated, a low-noise CCD or CMOS X-ray detector acquires as many Bragg reflections as possible to index Laue diffractions at specific RLPs. We offer a comprehensive crystal orientation system designed for real-time two-dimensional orientation mapping and mis-orientation measuring down to 0.05 degrees. These systems are available in both horizontal and vertical configurations, allowing users to scan along the axis of growth or to map the polycrystalline orientation of wafers.

Laue Single Crystal Orientation System: Compact | Motorised | Real-Time | Accurate

If you would like to learn more about our best-in-class Laue diffraction tool, you may be interested in hearing some Insights into Laue Cameras from our MD Daniel Brau. Or, if you have any questions, why not contact a member of the team today?