Laue Single Crystal Orientation System

A range of compact cabinet systems delivering high-accuracy in real-time for research and industry

Crystal orientation, quality control, and turbine blade inspection

Laue single crystal orientation systems are essential for crystal cutting, polishing, large-scale facility experiments, and industrial applications

such as turbine blade manufacturing. Their performance is defined by alignment accuracy, cycle time, and software usability.

Our range of systems integrate key innovations to deliver fast, accurate, and user-friendly Laue orientation solutions.

Find the right Laue system for your application

Laue-LT

-

Typical Exposure Time Range

120 s - 240 s -

Maximum Sample Size

L 50 x D 50 x H 26.5 mm -

Scanning Area

Horizontal: 50 x 26.5 mm Vertical: 50 x 50 mm -

Beam Size on Sample

Adjustable down to 1 mm -

Active Input Area

76 mm x 105 mm -

Accuracy Down To

0.2° -

Sample Alignment Camera (for precision positioning)

Not included as standard -

Energy Range

5 to 50 keV

Laue

-

Typical Exposure Time Range

1 s - 30 s -

Maximum Sample Size

Horizontal: L 250 x D 250 x H 40 mm Vertical: L 250 x D 150 x H 40 mm -

Scanning Area

Horizontal: 250 x 40 mm Vertical: 250 x 150 mm -

Beam Size on Sample

450 µm (250 µm fine focus) -

Active Input Area

155 mm x 105 mm -

Accuracy Down To

0.1° -

Sample Alignment Camera (for precision positioning)

Included as standard -

Energy Range

5 to 29 keV

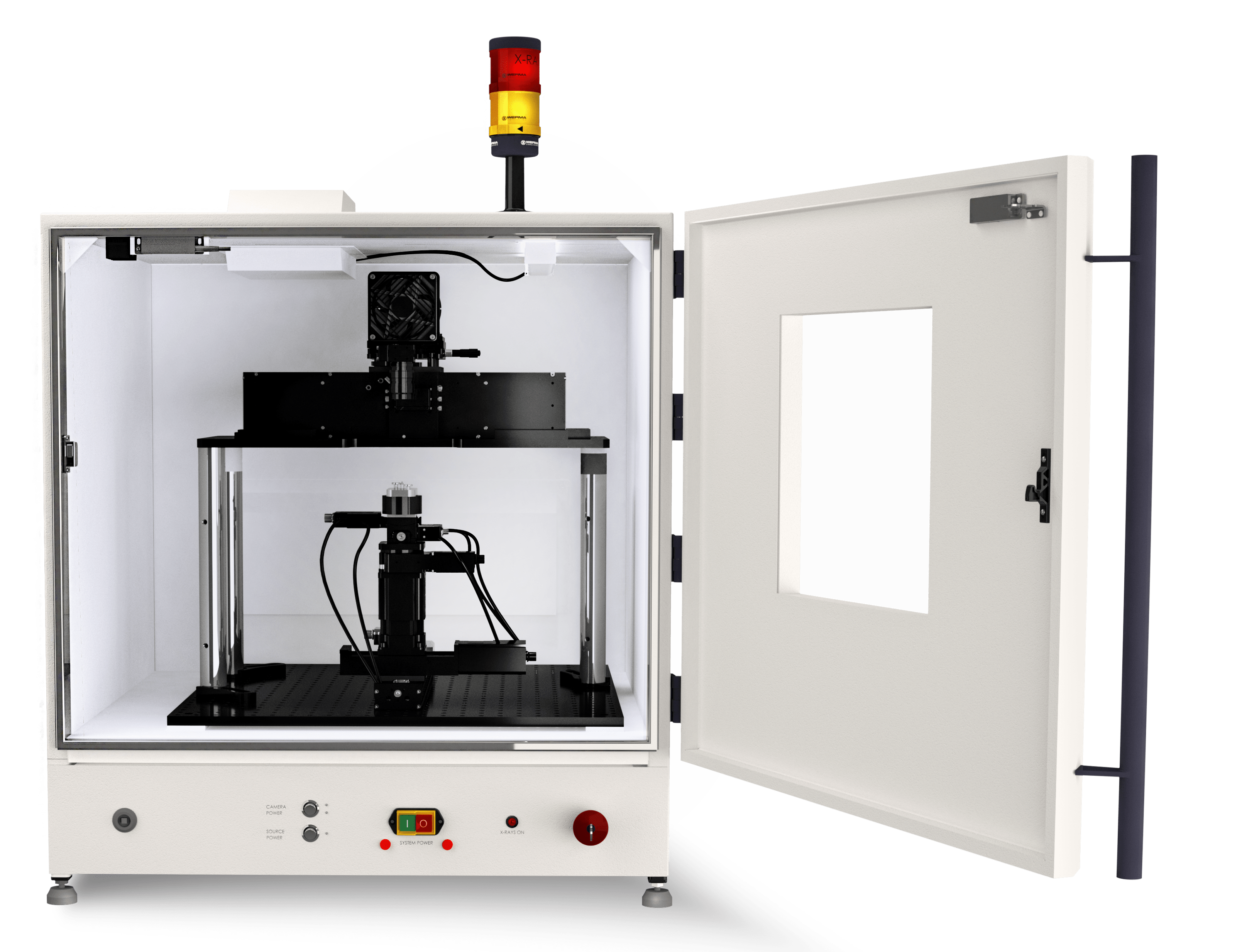

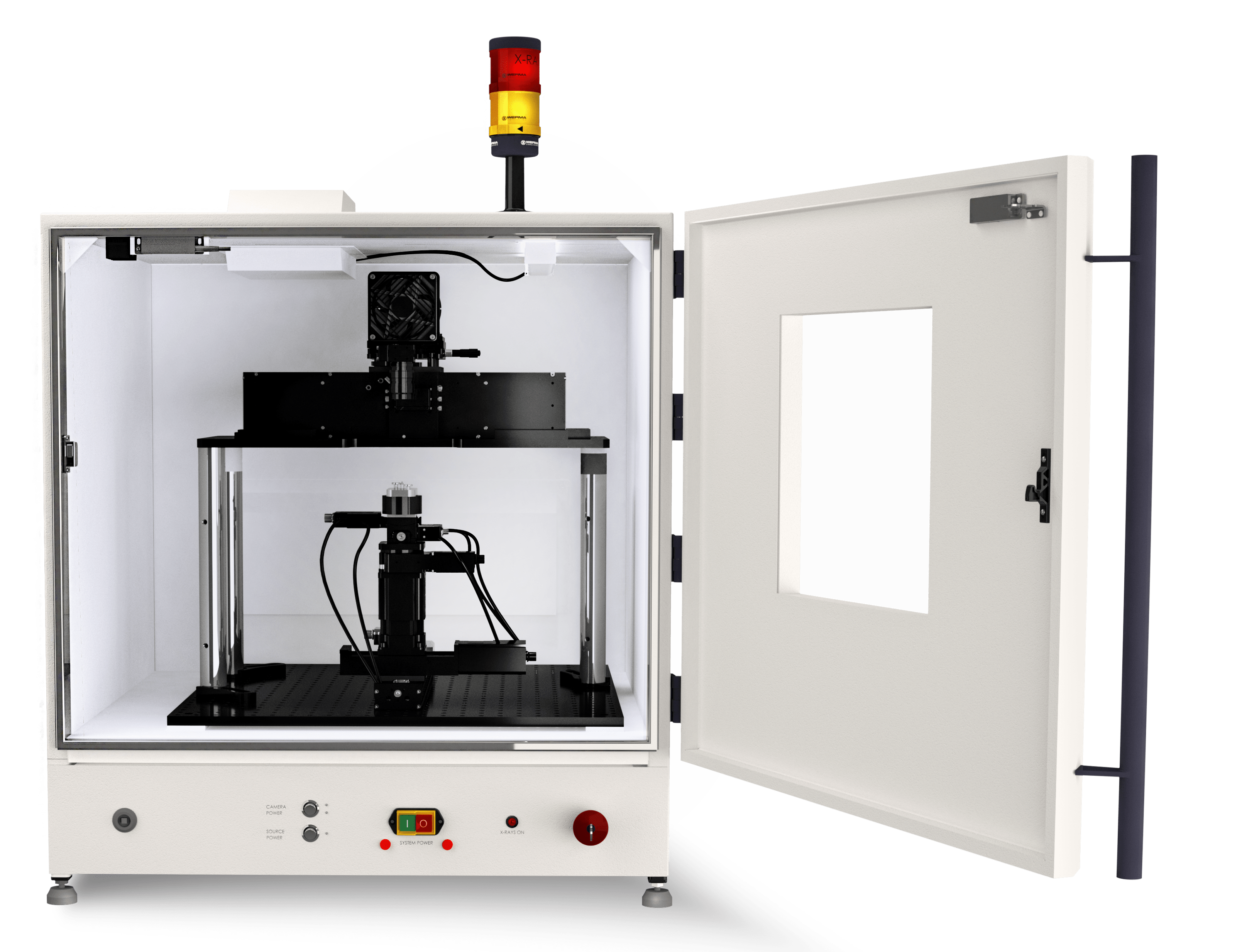

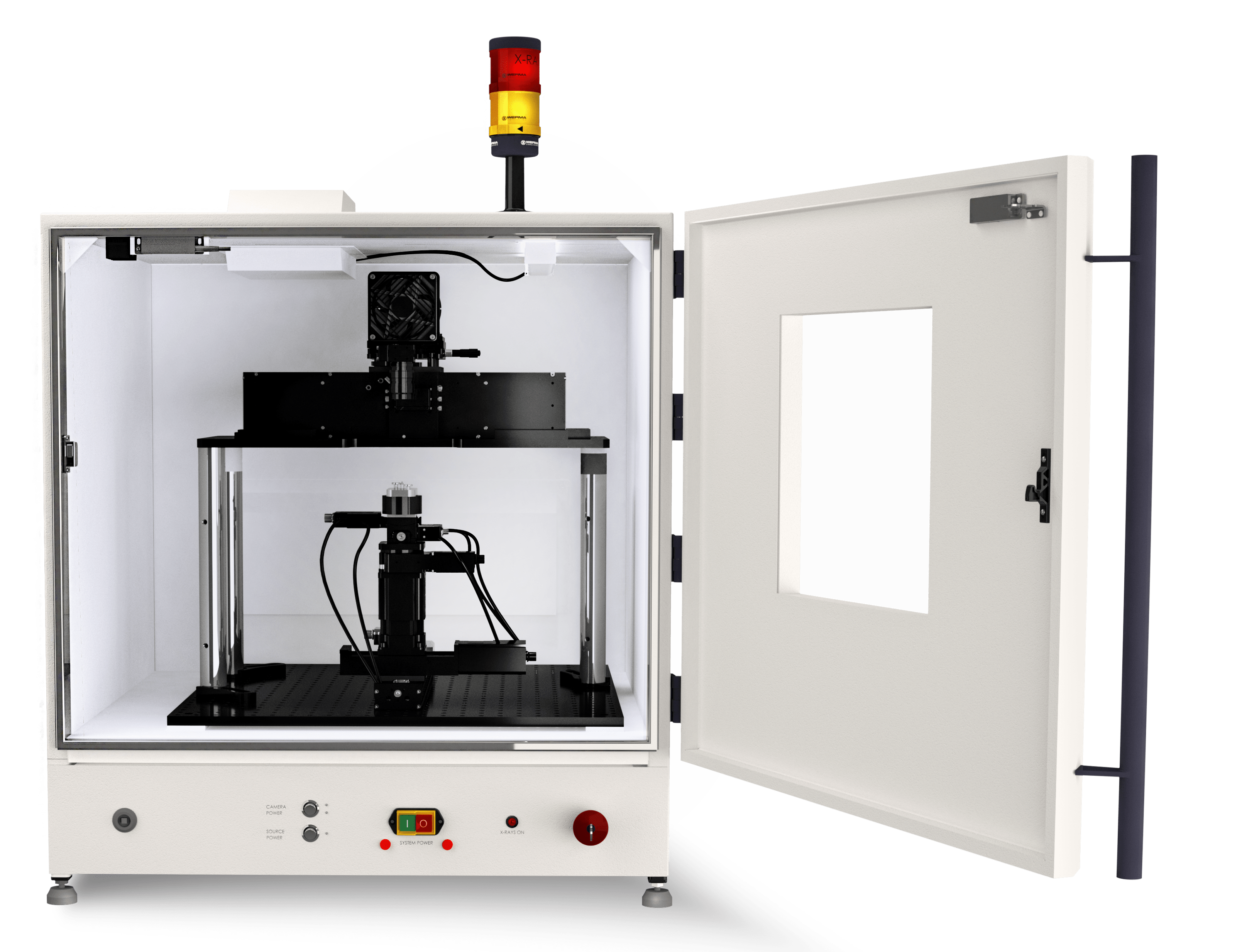

Laue-XT

-

Typical Exposure Time Range

1 s - 30 s -

Maximum Sample Size

L 450 x D 250 x H 250 mm -

Scanning Area

250 x 250 mm -

Beam Size on Sample

450 µm (250 µm fine focus) -

Active Input Area

155 mm x 105 mm -

Accuracy Down To

0.1° -

Sample Alignment Camera (for precision positioning)

Included as standard -

Energy Range

5 to 29 keV

Key Features

- Vertical, Horizontal, and Grain Map configuration options

- Plug-n-play compact cabinet system with air-cooled x-ray source

- Fast and precise alignment of small crystals

- CCD back reflection, high-resolution, high-sensitivity x-ray detector

- High-throughput sample screening options

- Proprietary focussing optics

- Manual to fully automated and motorised XYZ stages and goniometer

- Distance measurement tool for positioning

- Dedicated Laue software

Key Features

- Vertical and horizontal configurations

- Plug-n-play compact cabinet system with no chiller requirement

- Sealed x-ray tube with Tungsten target

- Zero maintenance, high-resolution, high- sensitivity, back reflection x-ray detector

- Class-leading x-ray optics solution

- Manual or motorised XYZ stages and goniometer

- Distance measurement tool for positioning

- Fast and precise alignment of crystals

- High-throughput sample screening options

- Reference Si sample

- Dedicated Laue software with micro scripting language for full automisation

- Custom workbench for cabinet with space for PC, monitor, keyboard and mouse

All systems include

- Pixel binning options

- Reference Si (or Sapphire) sample

- X-ray source alignment camera

- Sealed x-ray tube with Tungsten target

- PSEL X-ray Generator

- Single mains power connection

- Cusom workbench for cabinet, monitor, keyboard and mouse

Trusted by leading institutions

“The Photonic Science Laue is our system of choice as we have found it very dependable. Beyond the accuracy and relia- bility, the major feature is the convenience and speed of the system... it runs off a normal wall plug and quickly boots up to check your crystals immediately. It really is the best value that I have found on the market, with the complete kit deliv- ered onsite with an installation video - you set it up and, in an hour or two, you are ready to go.”

Gavin Hester PhD, Assistant Professor, Dept. of Physics, Brock University

“The Laue Crystal Orientation System exceeded my expectations, providing an excellent solution for aligning small samples with motorized rotations. The installation process was smooth, and I appreciated the team's customizations to the sample height motors and software, as well as their attention to local safety rules.Overall, it's the best commercial system for Laue diffraction, with a knowledgeable and accommodating support team.”

Mark Dean, Brookhaven National Laboratory

Learn more about Laue

Further Reading

Using x-ray back reflection diffraction.

Achieving high flux with low power sources.

Frequently Asked Questions

What is the Laue Crystal Orientation System used for?

The Photonic Science Laue Crystal Orientation System is designed to capture and analyse Laue diffraction patterns for single-crystal and polycrystalline materials. It is widely used for real-time crystal orientation, crystal cutting and preparation, wafer inspection, turbine blade analysis, and other industrial and research applications requiring precise crystallographic alignment.

What level of orientation accuracy does the system provide?

The system delivers crystal orientation measurements with an accuracy of up to 0.1°, enabling fast and precise alignment of both small and larger samples.

What configurations are available?

There are three configurations:

- Vertical Laue: High-throughput scanning of multiple crystals, ideal for easy mounting and sub-millimetric samples.

- Horizontal Laue: Traditional geometry, optimised for crystal cutting and reflection identification.

- Grain Map: Vertical configuration with specialised optics and software for orientation mapping of polycrystalline wafers.

What types of samples can be analysed?

The system can analyse a wide range of crystalline materials, including:

- Single crystals

- Semiconductor wafers

- Turbine blades

- Photovoltaic and scintillation crystals

- Polycrystalline silicon wafers (with Grain Map configuration)

Is the system easy to install and operate?

Yes. The system comes as a plug-and-play compact cabinet, requiring no custom bench or additional services. Users can set it up within a couple of hours, guided by an installation video. Its dedicated software ensures intuitive operation, even for non-expert users.

Is the system fully automated?

The system offers fully automated, motorised XYZ stages and goniometers, but manual operation is also available for users who prefer it. Automated Laue analysis software speeds up peak indexing and crystal orientation.

Does the system require a water chiller?

No. The system uses an air-cooled x-ray source, eliminating the need for a water chiller while maintaining high-brilliance performance.

What detector technology is used?

It features a high-resolution, high-sensitivity CCD x-ray detector with a large active area (155 × 105 mm) and a resolution of 2,570 × 1,710 pixels. This allows precise measurement of Laue diffraction spots.

How small is the x-ray beam?

The standard beam size is 450 µm, with an optional fine focus of 250 µm available in the vertical configuration, allowing accurate analysis of small crystals.

What software is included?

The system includes a dedicated Laue software suite that controls the stages, x-ray source, and detector, and performs:

- Automatic diffraction peak detection and indexing

- Misorientation calculations

- Multiuser workflow

- Data export in CSV for quality assurance

- Macro interface for repetitive tasks

- Remote access support for ongoing service