News

Neutron Laue Diffraction System ILL Grenoble

20th Oct, 2020

Neutron Laue diffraction system designed with the ILL Grenoble: Written By John Allibon Diffraction Group Institut Laue-Langevin Grenoble.

The Institut Laue-Langevin (ILL) is a large-scale facility, part of a multi-national science research campus in Grenoble France. It consists of a high flux reactor providing neutron beams to 35 or so instruments that perform a variety of measurements, mainly to explore structural material science. These are offered to and used by the European (member states) scientific community, usually from universities.

Modern large area neutron detectors, often based on He³, are generally expensive, lengthy to build, and require complex electronics to function and for communication with their control systems.

Another approach for less quantitative and more qualitative applications is to use neutron scintillators which can be « read » with CCD-based cameras. Improvements with resolution, dynamic range, and speed of communication over the last few years have made these viable and much cheaper alternatives for some applications.

Our first machine, built by and in collaboration with Photonic Science and Engineering (PSEL), is Orient-Express. This is a classic Laue camera setup, used for rapid inspection of crystal quality and orientation. It consists of 2 PSEL Neutron Cameras looking at a flat scintillator.

Orient Express Neutron Diffraction Beamline ILL

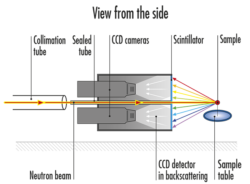

The incident white neutron beam passes through the camera, normally in a backscattering position, to strike the sample. The diffraction pattern is read back from the cameras, stitched together, and displayed on the computer screen. Exposure time is generally a few seconds up to a few minutes. The first version was built about 15 years ago and provided a revolution over the old method needing film and a dark room development facility. The machine was upgraded for a superior CCD and faster communication electronics about five years ago.

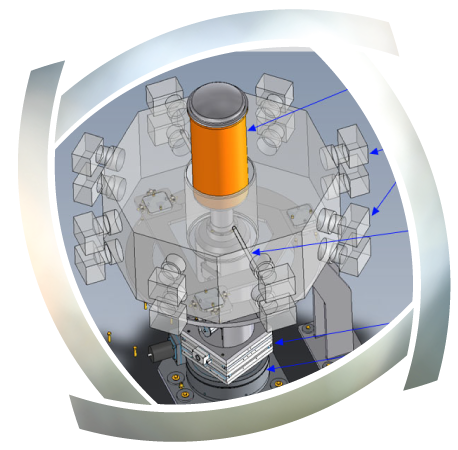

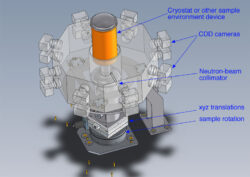

Based on the experience gained with Orient-Express we decided together to build Cyclops, somewhat more ambitious. It consists of 16 cameras arranged in a double-height octagon. These are focused onto a cylindrical scintillator with the sample in the center. The sample space was made large enough to take a variety of sample environmental control equipment, generally for low temperatures. The cameras are connected back to their controlling PC with GigE connections. The stitching, dynamic range stretching, flat field corrections, and balancing is done here with PSEL software.

Cyclops-Neutron Diffraction System ILL Grenoble

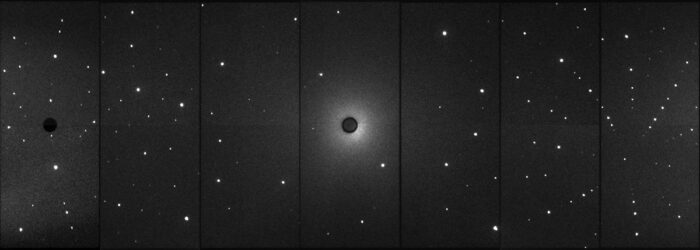

The whole machine is driven from a Linux computer which controls sample orientation and conditions and drives the PC as a black-box detector through the incorporated socket connection. The same controlling software is used on Orient-Express. The stitched image size is 7680 x 2400 (x16bit) pixels and represents 70% of a complete enveloping spherical detector.

We typically take acquisitions of a few minutes each at a series of, for example, temperatures. We can make a film of the series of images and can see easily if and where structural changes take place. The overall low background allows us to perform long (>1h) acquisitions if necessary. In addition, reasonable quality structural analysis can be quickly and easily performed.

We are fortunate that diffraction spots tend to be large – spread over quite a few pixels, this means that these can be easily differentiated from spots caused by gamma, cosmic ray, or dead pixels.

Cyclops Beamline Ruby Neutron Diffraction Image

John Allibon ILL

“We were novices in the world of imaging. Photonic Science & Engineering has massive experience with building image intensified cameras and scintillators.

They have understood our needs and built these instruments (and others) as turn-key detector installations and helped with the in-situ setup.

Their windows-based control software is complete, easy to use, and reliable. They have, on several occasions, modified this according to our requests. Importantly, camera reliability problems have been addressed successfully.

“Last, but not least: many of the people in the PSEL team have become good friends”

Photonic Science & Engineering would like to thank John Allibon and Bachir Ouladdiaf of Institut Laue-Langevin, Grenoble for providing images & presenting this case study.

Download pdf Neutron Laue Diffraction System ILL Grenoble France

If you have specific requirements and would like to talk to a sales representative about a potential solution, we can help. Contact a member of the Photonics Science team today to learn more about our custom Neutron Cameras solutions.

Further reading :

OrientExpress A new system for Laue neutron diffraction

CYCLOPS – a reciprocal-space explorer based on CCD neutron detectors